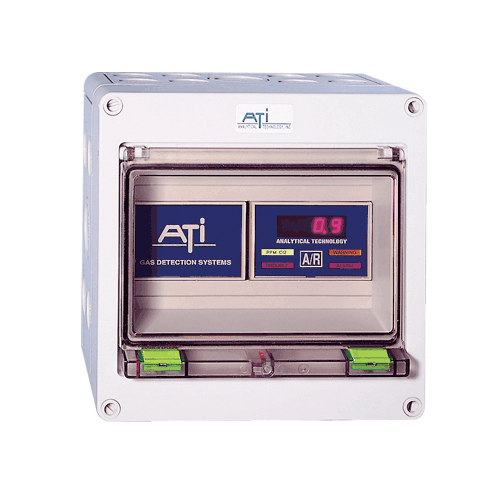

Gas Detection Transmitters

Gas detection transmitters come in all shapes and sizes. Some require simple 4-20 mA transmission. Some are better suited to local alarm relay functions. Some relays require both. And increasingly, digital communication directly to the transmitter is desirable. That is why AFC International offers a variety of gas transmitters from Analytical Technology, Sensor Electronics, RKI and Rae Systems (Honeywell).

Select by Gas / Chemical

Acetone Acetylene Acid Gases Alcohol Ammonia Arsine Benzene Boron Trichloride Boron Trifluoride Bromine Carbon Dioxide Carbon Monoxide Chlorine Chlorine Dioxide Chlorofluorocarbons (CFC) Combustible Diborane Dichlorosilane Dimethylamine Disilane Ethanol Ethylene Ethylene Oxide Fluorine Formaldehyde Freon Gamma Germane Hexamethylene Diisocyanate (HDI) Hexane Hydrazine Hydrocarbons Hydrogen Hydrogen Bromide Hydrogen Chloride Hydrogen Cyanide Hydrogen Fluoride Hydrogen Peroxide Hydrogen Selenide Hydrogen Sulfide Hydrogenated Xylene Diisocyanate (H6XDI) Iodine Isobutane Isobutylene Isophorone Diisocyanate (IPDI) Isopropyl Alcohol LPG Mercury Methane Methyl Bromide Methyl Chloride Methyl Ethyl Ketone Methyl Mercaptan Methylene bis-(4-cyclohexyisocyanate) (HMDI) Methylene Bisphenyl Isocyanate (MDI) Nitric Oxide Nitrogen Nitrogen Dioxide Nitrous Oxide Oxygen Ozone Phosgene Phosphine Photo Ionization Detector PID Silane Sulfur Dioxide Toluene Toluene Diisocyanate (TDI) Vinyl Chloride VOC VOCs Volatile Organic Compounds Xylene Xylene Diisocyanate (XDI)

Select by Manufacturer

Analytical Technology Inc. Honeywell Analytics Inc Rae Systems by Honeywell RKI Instruments Sensor Electronics Corp Store

EC-600 Carbon Monoxide Monitor

$10.00 – $945.00Select options

This product has multiple variants. The options may be chosen on the product page

OX-600 Oxygen Monitor

$10.00 – $785.00Select options

This product has multiple variants. The options may be chosen on the product page

RI-600 Carbon Dioxide Monitor

$10.00 – $980.00Select options

This product has multiple variants. The options may be chosen on the product page

RKI Email / Text Generator for Fixed Systems

$560.00 – $840.00Select options

This product has multiple variants. The options may be chosen on the product page