Description

Description

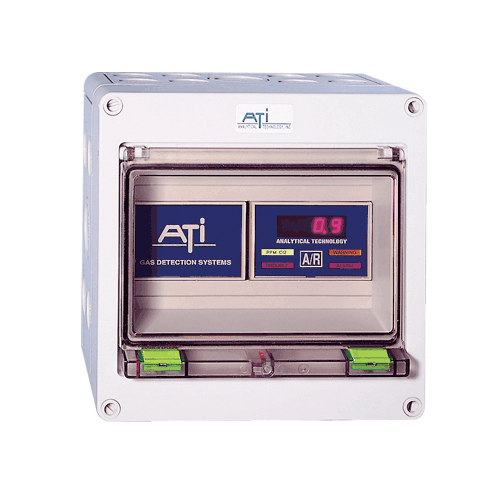

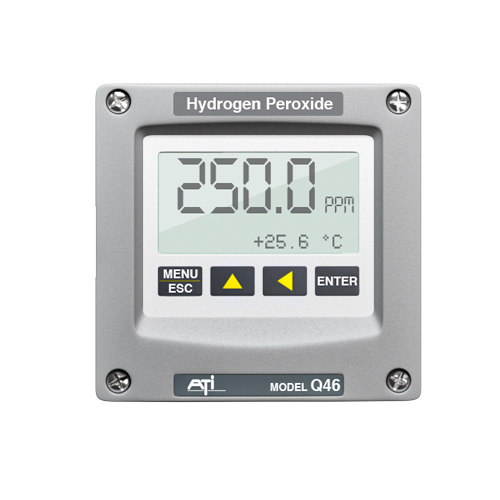

GasSens A14/A11 gas detection system is a flexible component system providing a variety of options to meet individual gas detection and alarm requirements. Economical and low maintenance, this system is your best choice for reliable leak detection. GasSens detection systems consist of individual modules that can be located where required. Sensor/transmitters located in the area where gas leakage or buildup might occur, provide the basic measurement for the system. Sensor transmitters are available in either NEMA 4X or explosion-proof versions and can be supplied with ATI’s exclusive Auto-Test automatic sensor testing system.

Receiver modules provide the electronic brains for the detection and alarm system. Each compact module includes a digital display of gas concentration, isolated analog output, and 4 relay outputs. Receivers may be located up to 1,000 feet from sensor/transmitters for remote indication or can provide local control functions such as valve shut off while transmitting a 4-20 mA signal to remote displays or dataloggers.

Receiver modules provide an interface between the detection system and external alarming and data logging requirements. One module is used with each sensor/transmitter.

The GasSens A14/A11 gas detection system employs electrochemical sensors developed and manufactured by ATI. Expertise in electrochemistry and sensor design provide the foundation for leak detection systems that perform continuously with minimal maintenance. Sensors are rated for ambient temperature from -25 to 50ºC, allowing both indoor and outdoor applications. Excellent zero stability and high sensitivity and selectivity combine to make ATI sensors the best available.

Gas sensors are closely coupled to a digital transmitter for excellent noise immunity and the ability to transmit long distances using unshielded cable. The transmitter is powered from the receiver module and uses a unique current pulse position technique to send information to the receiver over a two wire connection. The receiver connection in not polarity sensitive, virtually eliminating the possibility of incorrect transmitter wiring. Sensor/transmitters can be located up to 1,000 feet from receiver modules.

Sensor/transmitters are housed in shielded NEMA 4X enclosures for use in almost any industrial environment and are designed to meet intrinsic safety standards. An explosion proof version is available.

Auto-Test – Savings & Safety

A major expense in gas detection systems is the cost of regular testing to ensure that sensors are responding. This requires a technician to inspect sensors weekly and apply a small amount of gas manually to check response. ATI has developed a unique system to reduce this maintenance requirement.

Available on the GasSens A14/A11 Gas detection system is an option called “Auto-Test.” This option consists of an electrochemical gas generator closely coupled to the sensor. Every 24 hours, the receiver automatically activates the generator, producing a small amount of gas that diffuses into the sensor, just as it would if a gas leak occurred. The microcomputer is the receiver analyzes the output of the transmitter to determine that the sensor is responding normally. When proper sensor response is detected, the generator is turned off and the system goes back to normal operation. If no sensor response is detected, the TROUBLE light on the receiver will flash and the trouble relay will activate. During testing, alarm relays are inhibited so that external alarms are not activated.

The Auto-Test feature ensures that each sensor is regularly tested with gas. Premature sensor failure or blockage of the sensor membrane is quickly detected. In addition, self-testing will alert maintenance personnel when a sensor has reached the end of its useful life. Since sensors normally last anywhere from 12 months to over 3 years, this feature allows users to determine when sensor replacement is needed.

Power Supply Module

A compact universal power supply in a DIN rail module similar to the receiver was developed. The power supply will accept any AC or DC input from 85 to 225 volts, without adjustment.

Other options include a battery back up system and horn and strobe light options.

Tags: Acetylene gas detector, Alcohol gas detector, Ammonia gas detector, Arsine gas detector, Bromine gas detector, Carbon Monoxide gas detector, Chlorine gas detector, Chlorine Dioxide gas detector, Diborane gas detector, Dimethyl Amine (DMA) gas detector, Ethylene Oxide gas detector, Fluorine gas detector, Formaldehyde gas detector, Germane gas detector, Hydrogen gas detector, Hydrogen Chloride gas detector, Hydrogen Cyanide gas detector, Hydrogen Fluoride gas detector, Hydrogen Peroxide gas detector, Hydrogen Selenide gas detector, Hydrogen Sulfide gas detector, Iodine gas detector, Nitrogen Dioxide gas detector, Nitric Oxide gas detector, NOx gas detector, Oxygen gas detector, Ozone gas detector, Phosgene gas detector, Phosphine gas detector, Silane gas detector, Sulfur Dioxide gas detector