Description

Description

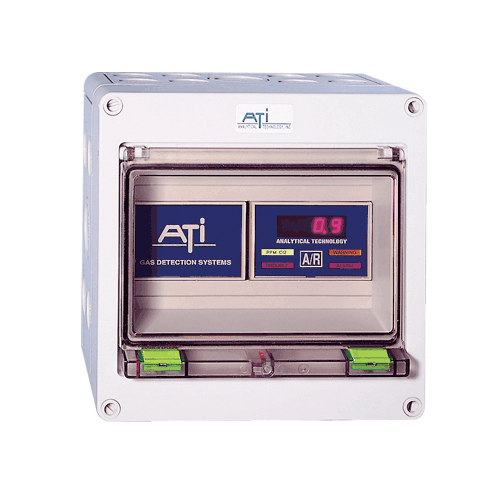

The F12IS Digital Gas Transmitter is an Intrinsically Safe (IS) version of ATI’s explosion proof D12 transmitter. In its standard form, it is designed for detection of a variety of toxic gases in hazardous area applications requiring IS devices. In addition, it is also well suited for all general purpose applications where toxic gas measurement is required. For IS installations, this transmitter is also available with a Hart communication option.

Series F12IS Digital Gas Transmitter use ATI’s standard smart sensors for maximum flexibility. Sensors are easily exchanged and contain all calibration constants in sensor memory, eliminating the need for field calibration of transmitters. Sensors may be calibrated on the bench and then simply plugged into the transmitter. Calibration data is read into the transmitter automatically and no other adjustments are normally required. For general purpose gas detection applications, the F12IS transmitter is also available in Non-IS versions. One version provides for easy interface to RS-485 networks using a standard MODBUS communication protocol. A second version provides a complete AC powered instrument with 3 alarm relays (SPST) available for external alarming.

Specifications

| Range |

User adjustable within limits of selected sensor module |

| Response Time |

Sensor dependent |

| Accuracy |

Generally ±5-10% of value, but limited by available calibration gas accuracy |

| Electronic Repeatability |

±1% of full scale |

| Electronic Linearity |

±0.5% of full scale |

| Zero Drift |

Less than 2% of full scale per month, non-cumulative |

| Span Drift |

Application dependent, but generally less than 3% per month |

| Alarm Relay Option |

Three SPST 5A@ 230 VAC resistive |

| Analog Output |

4-20 mA, 600 ohms maximum at 24 VDC |

| Serial Interface |

HART digital signlaing over the 4-20 mA current loop, Optional |

| Power |

12-28 VDC, 25 mA maximum

75 mA Maximum with heated sensor |

| Enclosure |

IP65 Polycarbonate with SS hardware. Weatherproof and corrosion resistant |

| Sensor Type |

Electrochemical for toxic gases and oxygen |

| Controls |

Four dome type push buttons, remote alarm reset input |

| Temperature |

-30° to + 60°C for toxics, -10°C minimum for oxygen sensor |

| Weight |

1.5 pounds |

Sensor Specifications

| Gas |

Range |

Catalog No.

|

| Acetic Acid |

0-100/500 ppm |

00-1045 |

| Acid Gases |

0-10/200 ppm |

00-1038* |

| Acetylene |

0-200/2,000 ppm |

00-1057 |

| Alcohol |

0-50/500 ppm |

00-1043 |

| 0-500/2,000 ppm |

00-1044 |

| Ammonia |

0-50/500 ppm |

00-1010* |

| 0-500/2,000 ppm |

00-1011 |

| Arsine |

0-500/2,000 ppb |

00-1024 |

| 0-10/200 ppm |

00-1025 |

| Bromine |

0-1/5 ppm |

00-1000* |

| 0-5/200 ppm |

00-1001* |

| Carbon Monoxide |

0-50/1,000 ppm |

00-1012* |

| Chlorine |

0-1/5 ppm |

00-1002* |

| 0-5/200 ppm |

00-1003* |

| Chlorine Dioxide |

0-1/5 ppm |

00-1004* |

|

0-1/5 ppm, low Cl2 Response

|

00-1425*

|

| 0-5/200 ppm |

00-1005* |

|

0-200/1,000 ppm

|

00-1359

|

| Diborane |

0-500/2,000 ppb |

00-1026 |

| 0-10/200 ppm |

00-1027 |

| Dimethyl Amine |

0-100/200 ppm

|

00-1450*

|

| Ethylene Oxide |

0-20/200 ppm |

00-1039* |

| Fluorine* |

0-1/5 ppm |

00-1006* |

| 0-5/200 ppm |

00-1007* |

| Formaldehyde* |

0-20/200 ppm |

00-1040* |

|

0-500/2,000 ppm

|

00-1349*

|

| Germane |

0-500/2,000 ppb |

00-1028 |

| 0-10/200 ppm |

00-1029 |

| Hydrogen |

0-1/10% |

00-1013 |

| 0-500/2,000 ppm |

00-1041 |

| Hydrogen Bromide* |

0-10/200 ppm |

00-1455* |

| HC Sensor |

Specify Gas |

00-1516 |

| Hydrogen Chloride* |

0-10/200 ppm |

00-1017* |

| Hydrogen Cyanide* |

0-10/200 ppm |

00-1018* |

| Hydrogen Fluoride* |

0-10/200 ppm |

00-1019* |

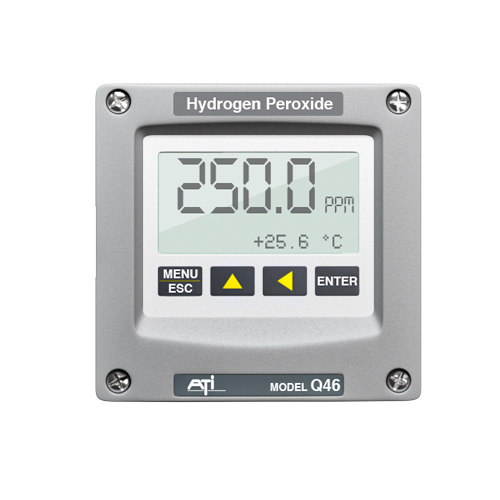

| Hydrogen Peroxide* |

0-10/100 ppm |

00-1042* |

|

0-200/2,000 ppm

|

00-1169

|

| Hydrogen Selenide |

0-500/2,000 ppb |

00-1030 |

| 0-10/200 ppm |

00-1031 |

| Hydrogen Sulfide* |

0-10/200 ppm |

00-1020* |

| 0-200/1,000 ppm |

00-1469 |

| Iodine* |

0-1/5 ppm |

00-1036* |

| 0-5/200 ppm |

00-1037* |

| Nitrogen Dioxide |

0-10/200 ppm |

00-1022* |

| Nitric Oxide |

0-50/500 ppm |

00-1021 |

| Oxygen |

0-5/25% |

00-1014 |

| Ozone* |

0-1/5 ppm |

00-1008* |

| 0-5/200 ppm |

00-1009* |

|

0-200/1,000 ppm

|

00-1358

|

| Peracetic Acid |

0-1/5 ppm |

00-1704 |

| 0-10/100 ppm |

00-1705 |

| Phosgene |

0-1/5 ppm |

00-1015 |

| 0-5/100 ppm |

00-1016 |

| Phosphine |

0-500/2,000 ppb |

00-1032 |

| 0-10/200 ppm |

00-1033 |

| 0-200/2,000 ppm |

00-1034 |

| Silane |

0-10/200 ppm |

00-1035 |

| Sulfur Dioxide |

0-10/500 ppm |

00-1023* |

(*) Indicates Auto-Test available