Description

Description

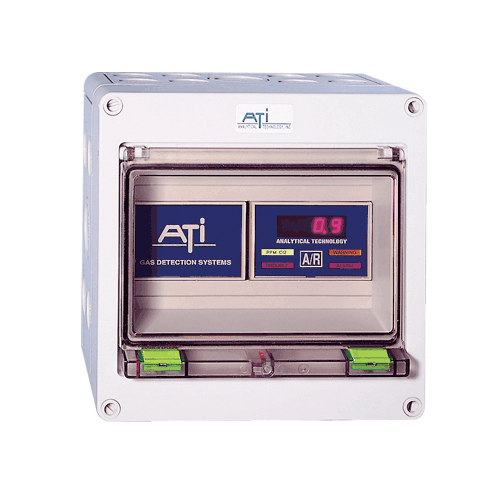

ATI’s B12 gas detection transmitters are loop-powered instruments that transmit a 4-20 mA signal linearly proportional to gas concentration. Operated from a 24 VDC power supply, the transmitter will drive loads up to 675 ohms, sufficient for most monitoring applications. Alternatively, the unit can operate at 12 VDC with reduced output load for applications requiring battery operation.

These detectors are normally supplied with the sensor close coupled to the enclosure. However, for special applications, the unit can be supplied with separate sensors that can be located up to 25 feet from the transmitter. Sensor duct mounting adapters and sensor flowcells can also be provided for specific applications.

| Gas |

Maximum Range

|

|

| Acetylene |

0-500 ppm

|

0-2,000 ppm

|

| Acid Gases | ||

| Alcohol | ||

| Ammonia | ||

| Arsine | ||

| Bromine | ||

| Carbon Monoxide | ||

| Chlorine | ||

| Chlorine Dioxide | ||

| Diborane | ||

| DMA |

0-100 ppm

|

0-200 ppm

|

| Ethylene Oxide | ||

| Fluorine | ||

| Formaldehyde | ||

| Germane | ||

| Hydrogen | ||

| Hydrogen Chloride | ||

| Hydrogen Cyanide | ||

| Hydrogen Fluoride | ||

| Hydrogen Peroxide | ||

| Hydrogen Selenide | ||

| Hydrogen Sulfide | ||

| Iodine | ||

| Nitrogen Dioxide | ||

| Nitric Oxide | ||

| NOx |

0-50 ppm

|

0-500 ppm

|

| Oxygen | ||

| Ozone | ||

| Phosgene | ||

| Phosphine | ||

| Silane | ||

| Sulfur Dioxide |

B12 Gas Detection Transmitters for Wet Gas Streams

The B12 Wet Gas Detector was developed to provide reliable measurements in wet scrubber outlets for other gas streams that might be saturated with water vapor. These gas detector systems were specifically designed for monitoring strong oxidants (chlorine, bromine, chlorine dioxide, or ozone), acid gases (HCl or HF), and hydrogen.

Increasingly stringent air quality requirements have led to expanded use of wet scrubber systems to control pollutant gases released as air emissions. Chlorine storage facilities and chemical process plants are frequently required to scrub exhaust gas streams to remove halogen and acid gases. Unfortunately, monitoring reactive gas concentrations in moisture saturated air streams presents problems for standard diffusion gas sensors. Condensing water in these air lines can quickly blind standard diffusion transmitters, rendering them inoperable.

The basic B12 Wet Gas Detector system consists of a loop-powered 2-wire transmitter and a corrosion resistant sensor specifically engineered to operate at 100% RH. Gas sensors are designed for direct insertion into vent stacks, or may be used in a flow-cell if a sample can be pumped to the sensor. When remote display and alarm relay functions are required, the B12 wet gas transmitters can be connected to ATI’s B14 Gas Alarm Module. This receiver system will provide direct digital display of gas concentrations, plus 3 alarm set points, a remote alarm reset input, and retransmitted 4-20 mA output. The B12 wet gas transmitter may also be used separately and tied directly to the user’s DCS, PLC, or other equipment. Either way, the B12 Wet Gas Detector is an excellent solution to a difficult gas monitoring problem.