Description

Description

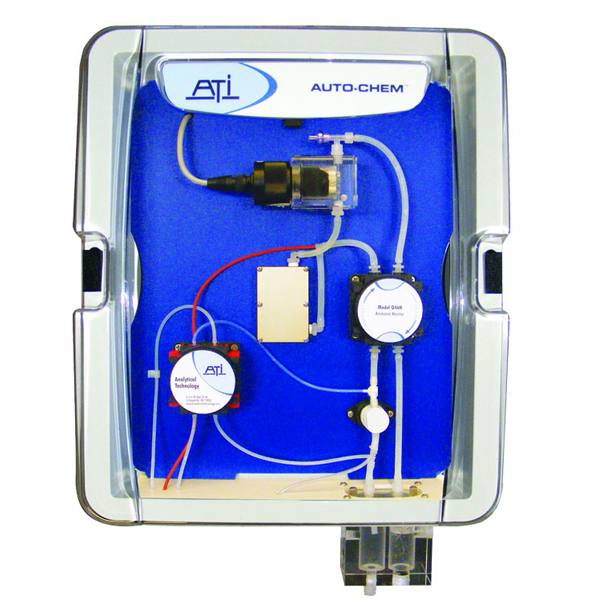

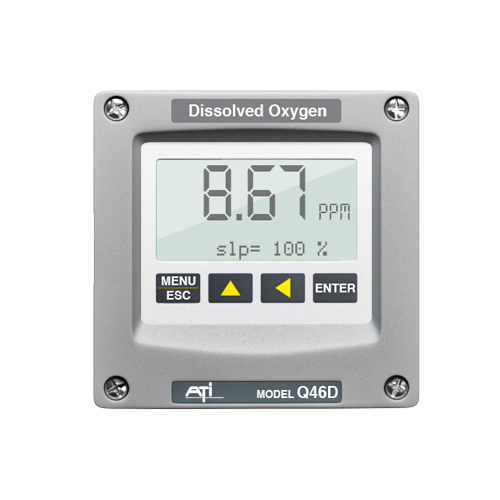

The Q46N Dissolved Ammonia Monitor from ATI was developed for a new approach to on line monitoring of ammonia that is easier to operate and less expensive than competitive systems. On line monitoring of Ammonia in water is of increasing importance due to the increased emphasis on nutrient reduction in lakes, streams and estuaries. Unfortunately, simple direct measuring sensors have not proven sufficiently reliable and rather complicated systems have been developed to address the measurement problem. These systems can be used but require substantial maintenance and are expensive to purchase.

Ammonia measurement is accomplished by the addition of three reagents, each of which is fed using a multichannel peristaltic pump. A stabilzer chemical is injected first to stop calcium precipitation in the tubing. After that, a solution containing free chlorine is injected which results in the conversion of ammonia to monochloramine.

NH4+ + HOCl = NH2Cl + H+ + H2O

The third reagent added quenches the above reaction by removing the excess free chlorine. This ensures that free ammonia in the sample stream is converted to monochloramine and dichloramine formation does not occur.

Once chloramine formation is complete, the sample is temperature stabilized and pumped to a flowcell containing a special amperometric membraned sensor. This sensor measures the monochloramine formed in the chemical system and produces a highly linear output that is amplified and displayed in the monitor.

Chloramination in potable water treatment has become common, especially in utilities with large distribution systems. the use of chloramines to reduce disinfection by products and to provide disinfectant protection throughout a large pipe network has proven useful but does present potential water quality problems if not controlled properly.

A carefully controlled chloramination system will result in the conversion to all free chlorine to monochloramine with only a slight excess of ammonia. This excess ammonia, called “free ammonia”, should be kept as low as possible to avoid the formation of nitrites and nitrates in the distribution system.

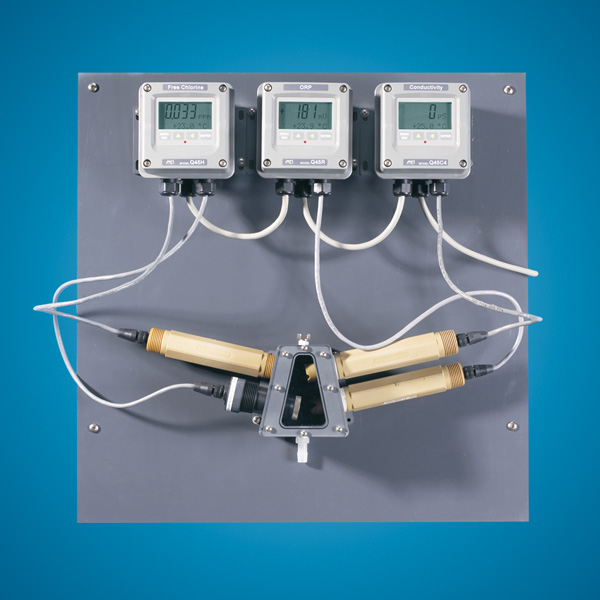

Minimizing the free ammonia concentration requires the accurate measurement of free chlorine to pace the ammonia addition, and also requires an accurate measurement of residual free ammonia. A special version of the Q46N Ammonia Monitor provides the capability of monitoring free ammonia by continuously measuring both total ammonia and monochloramine concentrations. free ammonia concentration is then derived from these values.

Two sensor integrated into the Auto-Chem chemistry system provide the required measurements. A sensor located in the inlet assembly measures monochloramine concentration in the cloraminated water. After addition of reagent, a second sensor measures the total ammonia concentration. The electronic monitor subtracts the monochloramine ammonia from the total ammonia and displays the free ammonia value.

Under normal operating conditions, refrigeration systems utilizing ammonia chillers have no ammonia in the process water. An ammonia monitor would display 0 ppm until a leak occurs. The Q46N Total Ammonia Monitor provides an automatic response verification system that confirms that the system is functioning properly. At user programmed intervals, a 1 ppm ammonia solution is introduced into the sample stream and the response is monitored to confirm the system is functioning properly. Outputs and alarms are inhibited during the test and and alarm is generated if the unit fails to respond. This system is not used for application where ammonia is normally present but is very useful for ammonia breakthrough applications.