Description

Description

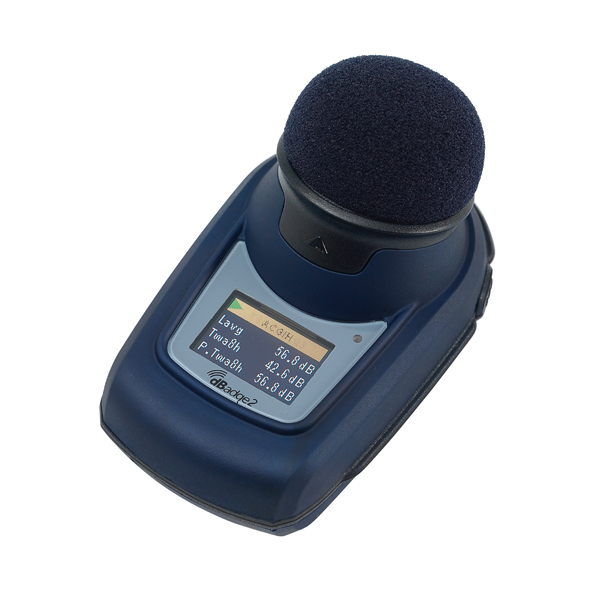

Intrinsically safe versions of the dBadge2 Noise Dosimeter are now available. The dBadge2 has been designed specifically to be used in potentially explosive areas in the oil and gas, petrochemical and pharmaceutical industries as well as being suitable for use in the mining industry. When Casella CEL introduced the revolutionary micro-sized dBadge cable-free, shoulder-mounted noise dosimeter to Industrial Hygienists and Safety professionals worldwide in 2006, it revolutionized personal noise exposure sampling in a significant way. Gone were all of the hassles and safety concerns of cable-mounted microphones – yet all the essential features of ‘traditional’ dosimeters (LCD data display, on-board control keys, IS approvals, ‘multiple metrics’ capture and secure data storage) were retained.

The dBadge2 has multiple simulated dosimeter capability to display noise exposure results according to differing regional or international protocols. Regardless of what you have displayed the dBadge2 always measures all parameters together. This helps ensure the correct parameters are always measured and you can choose how many parameters to display.

With it’s two button operation, the dBadge2 couldn’t be easier to use. After switching the dBadge2 on, apply the acoustic calibrator and press one button to perform calibration. Then hold both keys down to start a measurement. Each unit features lockable keys and display, automatic detection of acoustic calibrator, a color coded display and is easy to mount on the employees shoulder.

The dBadge2 is rated intrinsically safer for use in flammable atmospheres.

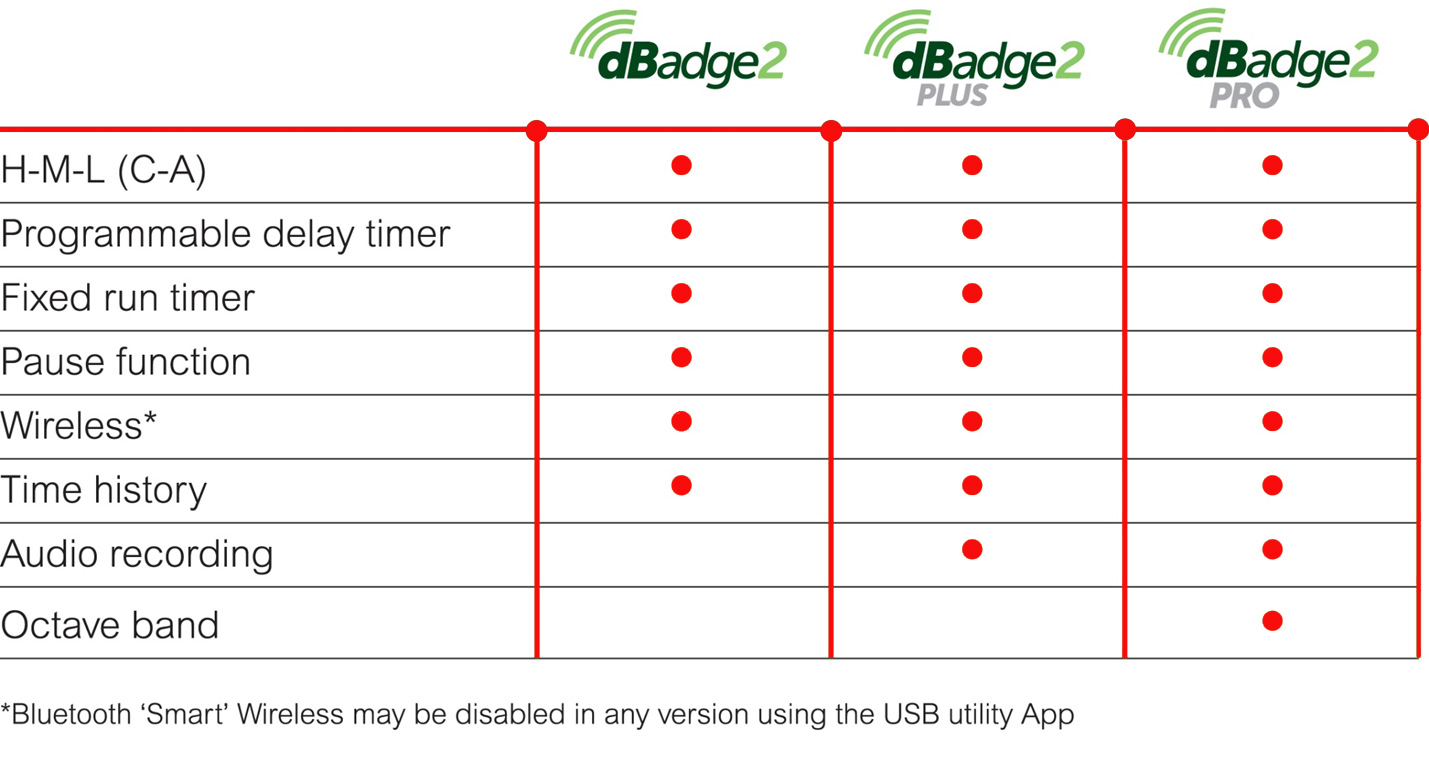

Different models of the dBadge2 are available with advanced functions depending on your requirements. Features available include audio notes at the start of a run to record measurement details, audio recording of level triggered events to identify anomalous noise, octave band analysis for selection of hearing protection and motion sensing to assist in measurement validation.