Description

Description

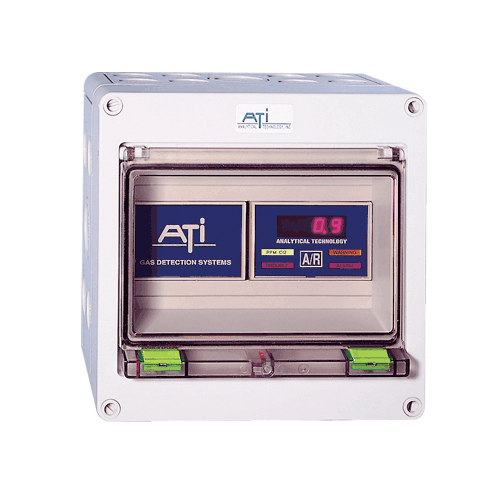

A21 Gas Sample Pump for Fixed Point Systems use a high quality diaphragm pump operated by a brushless DC motor to provide continuous sampling over long periods of time. Sampling pumps are rated for over 10,000 hours of continuous operation and diaphragms in the pump may be changed easily if necessary. The pump will draw samples against a vacuum of up to 10″ Hg for sampling negative pressure duct systems when necessary. In addition to the sampling pump, A21 systems contain various components needed to insure reliable sample measurement. A flowmeter mounted on the front panel allows the user to adjust the sample flowrate to the desired value, normally around 500 cc/min. Internal to the system is a loss of flow detector that will warn of sampling system problems that could compromise the gas measurement system. A loss of flow alarm light on the front panel provides local flow loss indication while an internal relay can be used to indicate this alarm remotely.

Monitoring gas levels using a sample draw system requires that the installation be done carefully and that the nature of the target gas be considered. In general, it is best to locate the gas sensor on the vacuum (inlet) side of the sample system. This insures that the gas sample will be measured before contacting pump or flow detection components that might affect gas concentration. This is especially important when sampling for reactive gases such as chlorine, sulfur dioxide or acid gases.

The type of tubing used on the portion of the sampling system between the sample point and the inlet port of the gas sensor is another important consideration. Reactive gases require the use of Teflon or other fluorocarbon tubing, while non-reactive gases can be samples using flexible PVC tubing. Sampling from gas streams saturated with moisture may require heated sample tubing, and the effect of condensation on the gas sensor must be carefully evaluated.

For fastest response, gas sampling lines between the sample point and the inlet to the gas sensor should be kept as short as possible. Sample transport time depends on the internal diameter of the sampling tube used as shown below. Values are based on a flowrate of 500 cc/min.

A21 Gas Sample Pump Flowrates

| 1/8″ id (3mm) tubing | 29 second per 100 feet |

| 3/16″ id (5mm) tubing | 65 seconds per 100 feet |

| ¼” id (6mm) tubing | 116 seconds per 100 feet |

ATI is now a Badger Meter Brand.