Description

Description

ATI’s Model Q46S/81 Dissolved Sulfide Monitor provides an improved method for measuring sulfides in solution.

Sulfides can be found naturally in well water and can build up in wastewater collection systems due to anaerobic conditions frequently found here. They are also used in mercury removal processes and are frequently found in tanning wastes. In drinking water systems, sulfides cause taste and odor problems. In wastewater systems, they can cause damage to concrete structures in collection systems and contribute to odor problems in treatment facilities.

Measurement of dissolved sulfide concentrations has been done primarily by the use of analyzers employing selective ion electrodes (SIE) for sensing. While providing adequate sensitivity, SIE based systems require frequent zero and span adjustments to maintain measurement accuracy. Because of this, most SIE based monitoring systems are relatively expensive and require frequent service.

Because measuring sulfides in a solution using an SIE is relatively difficult, the Q46S/81 Monitor takes a different approach to the measurement, employing a unique gas phase method to continuously monitor sulfide without contact between the sensor and the water sample. In operation, a small amount of sample is pumped into the system and mixed with acid. Under acidic conditions, the sulfide ion is converted to hydrogen sulfide gas as follows:

HS– + H+ = H2S

S= + 2H+ = H2S

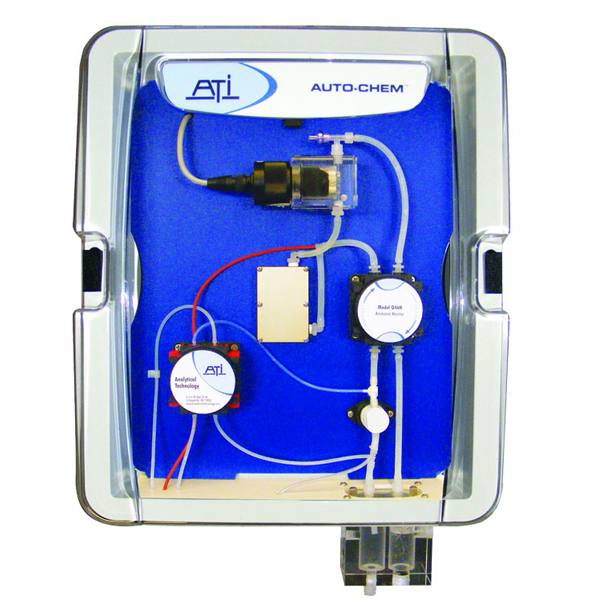

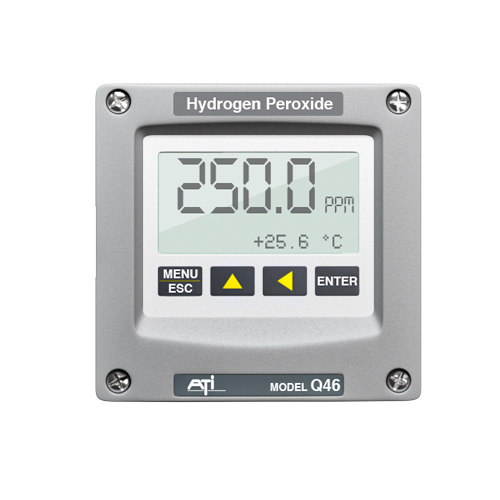

The mixed sample flows into a special chamber where the hydrogen sulfide is stripped from the sample. A gas conditioning module prepares the gas sample for measurement prior to contact with a special H2S gas sensor designed for the system. Sensor signals are amplified and displayed on a large format, back lit LCD display in the Q46S electronics unit.

A sample inlet overflow black is provided on the bottom of the chemistry module. Sample is connected using ¼” id flexible tubing, with a recommended flow rate of 5-20 gallons per hour. While the monitor uses only a small fraction of this sample, the higher flow keeps sample delivery times to a minimum. Excess sample simply overflows to a gravity drain chamber requiring a ½” id flexible tube.

Sulfide monitoring systems are extremely easy to operate and maintain, with acid usage of one gallon every 25 days at standard flow rates. sample and acid are pumped using long life peristaltic pump tubing that requires replacement approximately every 6 months. Pump heads are designed for easy tube changes, requiring about 10 minutes to replace both pump tubes. The sulfide sensor requires no maintenance other than an occasional visual inspection to insure that no deposits have collected due to airborne particulates.

The gas stripping technique for monitoring sulfide in solution provides an extremely sensitive on line monitor. measurements down to low parts per billion can be done easily and zero an span stability inherent in the senor allows for monthly calibration cycles.