Description

Description

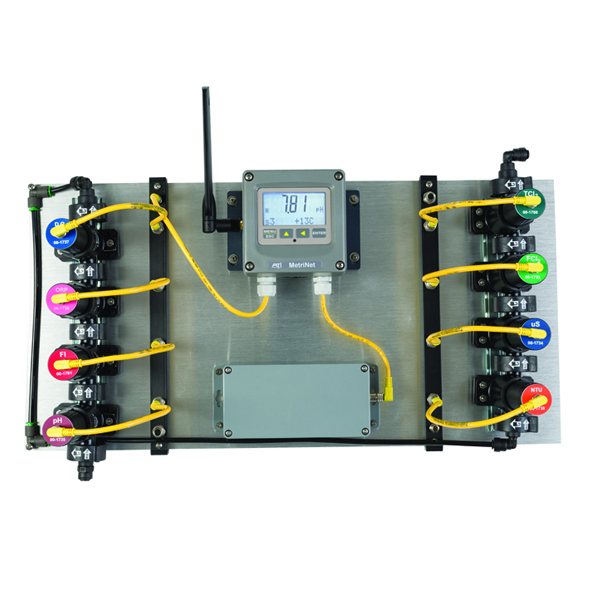

MetriNet Multi-Parameter Water Quality Monitor is a low power modular system for monitoring water quality parameters and collecting data at remote locations. This system is ideal for monitoring drinking water distribution systems, greenhouse water delivery systems, produce section misting systems and other clean water applications. MetriNet provides a robust monitoring package of up to eight different parameters and provides reliable collection and transmission of the acquired data. The system provides several methods for delivering this information including: cellular modem, WiFi, wired, Modbus, Ethernet/IP or Profibus DP, as well as cloud based data storage.

At the heart of the MetriNet Multi-Parameter Water Quality Monitor are a new series of smart digital sensors. M-Nodes are a complete sensor and transmitter housed in a miniaturized body. M-Nodes operate as independent modules that can be linked via a communication bus.

Sensor and bus connectors are IP-67 rated for maximum signal protection. Communication between M-Node sensors and the user data collection system is handled by the MetriNet Controller. The controller allows setup and calibration of M-Nodes, as well as storing data and transmitting data to either local or remote locations.

Flexibility is the key to the MetriNet system. The modular nature enables users to assemble a monitoring package that fit individual site requirement. All nodes plug directly into MetriNet systems and are powered directly from the communication bus. Nodes may be added or removed as needed and removal of a node will not affect system measurements.

Data sampling rates are user selectable to minimize power consumption. Data is stored locally in standard.csv file format for easy manipulation with spreadsheet programs. Cellular data transmission may be directed to commercial storage sites or directly to customer sites.

A typical MetriNet Multi-Parameter Water Quality Monitor that is connected to a continuous sample flow of 200ml/min will consume about 75 gallons per day. In many cases, this amount of water consumption will not be significant. However, in some cases, the user may wish to minimize the amount of water consumed by the MetriNet system.

The MetriNet controller provides a cyclic operating mode that allows the user to minimize the daily water consumption. When the solenoid valve is closed, there is no flow to the system and no measurements are taken. At user specified intervals, the solenoid valve is opened to allow fresh water into the system. Sample continues to flow for a selectable amount of time, then a measurement is taken and data is stored locally. When this cycle is complete, the solenoid is returned to a closed position and flow is once again restricted from the system.

Cyclic sampling can reduce water consumption to less than gallons per day at most sites.

MetriNet flow cells are modular, allowing assembly of from 1 to 8 flow chambers. Each chamber holds one M-Node sensor with a simple bayonet connection. A rotating lock ring clamps flow chambers together for easy assembly. A flow control device is integrated into the outlet fitting of the MetriNet flowcell to control sample flow to 0.2 lpm over 10-100 psig inlet pressure range. The first flow chamber is supplied with a push to connect fitting for rigid ¼” od tubing.

An internal mesh screen protects the flow element from particles larger than 100µm that might enter the system and is easily removed for inspection and cleaning if necessary. DIN rail mounting clips attached to each MetriNet flow chamber allow assembled flow systems to be easily rail mounted.

Power consumption requirements of traditional water quality monitors prevent their use in locations where AC power is not available. The low power design of the MetriNet system allows these monitors to operate on 12-24 VDC power, as well as battery power, without sacrificing reliability. To further improve power consumption, the MetriNet system allows users to operate in either continuous or cycle modes. In full continuous mode, power is constantly applied to M-Nodes and measurements are continuously taken. When operating in cycle mode, the measurement nodes are placed in “sleep mode” for much of the time. Every 15 minutes, the nodes are switched to “full power: for about 15 seconds in order to take a reading and store data. Operation in cycle mode extends battery life considerably.

The table below provides an estimate of power/battery requirements for the system.

| System Type |

Full Power Mode |

Low Power Mode |

| 12-24 VDC with modem | 43mA + 3 mA/node | 15 mA + 3 mA/node |

| 12-24 VDC without modem | 30 mA + 3mA/node | 15 mA + 3 mA/node |

| 12 V battery with modem | 12 mA + 3mA/node | 4 mA + 3 mA/node |

| 12 V battery without modem | 26 mA + 3mA/node | 4 mA + 3 mA/node |

Note: During modem operation, power draw can spike to about 150 mA for the duration of the data transfer. A typical daily data transfer takes about 3 minutes.

MetriNet controllers contain a GPS module so that users may automatically identify the exact location of an installation. Using the GPS data, sites can be easily tied to map locations. If a controller is moved to another location, the position change is again updated.

M-Node sensors are available for a variety of water quality parameters. users simply select the parameters required for a specific location and assemble them into an integrated system. All Nodes communicate on a common RS-485 sensor bus using Modbus protocol. Each M-Node has an IP-67 M8 water tight connector for external communication. Power for the M-Node system is also supplied via the RS-485 bus. Nodes may even be used independently by system integrators who wish to communicate directly with the nodes using their own PLC system.