Description

Description

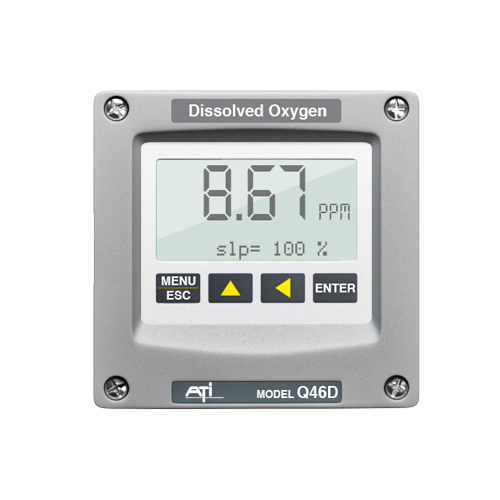

ATI’s Q46D Dissolved Oxygen Monitor is designed to provide reliable oxygen measurement and help reduce operating costs. Two types of sensing technologies are available for use with the Q46D system: Membraned Electrochemical and Optical (Fluorescence). Both sensors will provide reliable long-term performance with minimal maintenance. No hardware modifications are required to change from one sensor type to the other. The monitor can be configured for AC or DC power supplies and a portable battery-powered unit is available to meet a variety of monitoring needs.

Dissolved oxygen monitoring is critical to stable operation of biological processes in wastewater treatment plants. Whether it be fine bubble aeration, coarse bubble aeration, surface aeration or brush aerators, maintaining the proper DO level will produce better results. The Q46D Dissolved Oxygen Monitor is ideal for control applications where reliable performance is required 365 days a year.

Dissolved Oxygen monitoring is critical for aeration system process control. Optimization of the biological process, whether it’s removal or organic material, nitrification/denitrification, depends on maintaining proper DO levels. Controlling air flow to within the optimal range eliminates excess aeration which translates into significant energy savings.

When process conditions require frequent cleaning, our unique Q-Blast Auto-Cleaner can be used to keep the system operating nearly maintenance free. This time-proven system has been instrumental in providing years of worry free operation.

While both sensor types are capable of providing reliable dissolved oxygen readings, neither will function reliably unless the face of the sensor is kept clean. Over time, the treatment process deposits a biologically active film onto the surface of the sensor which impedes the transfer of oxygen. This build up can cause sluggish response to changing oxygen concentration and inaccurate oxygen values. The removal of this film, and other solids that may adhere to the sensor, is critical to the integrity of the oxygen readings. Sensor cleaning can be performed manually, but it’s time consuming and often neglected when other maintenance needs take precedence.

ATI’s Q-Blast option provides the ideal answer for automatic Dissolved Oxygen sensor cleaning. Employing a unique air-blast cleaning method, sensors can be cleaned as often as necessary without operator attention. Pulses of pressurized air delivered through a nozzle at the tip of the sensor remove accumulated solids from critical sensing surfaces, resulting in accurate and reliable measurements.

The Q-Blast Auto Clean assembly is housed in a NEMA 4X enclosure suitable for indoor or outdoor use. The system includes an integral compressor and air pulse control components, with a power supply for the entire air supply system incorporated into the design. A simple connection to the Q46D Dissolved Oxygen Monitor provides the sequence in for the system and also the operator to select cleaning frequencies as often as once every house to as little as once every 999 hours. To insure performance in extreme cold condition, a thermostatically controlled heater in the assembly, allowing operator down to -40°C.

The optical DO sensor operates on a light based principle called fluorescence which is a type of luminescence. Certain chemical compounds will absorb one type of light energy and then emit a different type of light energy. This light emission is called luminescence.

The active portion of the sensor has a metal-based compound embedded in a structural matrix. A light source inside the sensor illuminates this compound which absorbs light at a specific wavelength. The compound then emits light at a different wavelength which is picked up by a photodetector within the sensor. As oxygen diffuses into the active sensor material it interacts with the light absorbing compound and interferes with the mission reaction. This interaction, called quenching, causes the light absorbing material to release energy in a form other than light. The degree of quenching is proportional to the concentration of dissolved oxygen. The quenching reaction is reversible, which allows this sensor to measure increasing and decreasing concentrations of oxygen.

Optical sensor do not have internal electrolyte, so maintenance of this type of sensor is limited to changing the optical element. Over time, the element will lose the ability to absorb light due to a process called bleaching. With some sensors this process is greatly accelerated when it is exposed to direct sunlight and will cause irreversible damage to the sensor element. This optical sensor element is designed to last several years in normal operation. The sensor design allows for exposure to direct sunlight without damaging the sensor element.

Membraned type DO sensors have been used for DO monitoring and control for over 40 years and have proven to be consistently accurate and reliable. Properly designed, a membraned sensor will provide continuous service for a year or more without maintenance of any kind.

Galvanic oxygen sensors function in much the same way as a battery. The sensing elements consist of platinum cathode and lead anode, with a durable Teflon membrane isolating the sensor system from the liquid being measured. Oxygen diffuses through the membrane and is reduced to hydroxide ion on the surface of the cathode. This reaction generated current between the platinum and lead electrodes which is proportional to oxygen concentration. An RTD temperature element measures water temperature and corrects the sensor signal for its effect. The result is a DO measurement that’s accurate over an operating range of -5 to 50°C.

Both Standard and Auto Clean sensors use the same rebuildable DO cartridge. A durable 5 mil membrane insures that these sensor perform reliably in the most demanding applications, and a 2-mil membrane is available if faster response is needed. Modular design allows easy removal of the cartridge for service, eliminating the need for membrane changes out on the aeration tank. Spare cartridges can be prepared on the bench and quickly swapped to minimize downtime when service is required. Better yet, sensor cartridges can be rebuilt at very little cost.

The DO cartridge holders for both types of sensors contain a preamplifier potted in the holder assembly. This preamp reduces the potential for electrical interference with sensor signals and allows sensor cables to be extended long distances without signal loss.