Description

Description

Dechlorination of wastewater effluent is common practice in many wastewater facilities throughout the US. Strongly reducing sulfur compounds are used to eliminate chlorine residuals that might prove toxic to fish in the receiving stream. Because residual chlorine discharge limits are often very close to zero, monitoring residual values to comply with regulations has become very difficult and controlling residuals at values between zero and 10 or 20 ppb is often not achievable.

To meet stringent discharge limits, the sulfite or bisulfite used for dechlorination is added in slight excess, providing a small sulfite residual to insure complete dechlorination. ATI’s Q46/66 Residual Sulfite Monitor provides operators with a reliable tool for maintaining a small sulfite residual while reducing excess chemical consumption due to overfeed.

Theory of Operation

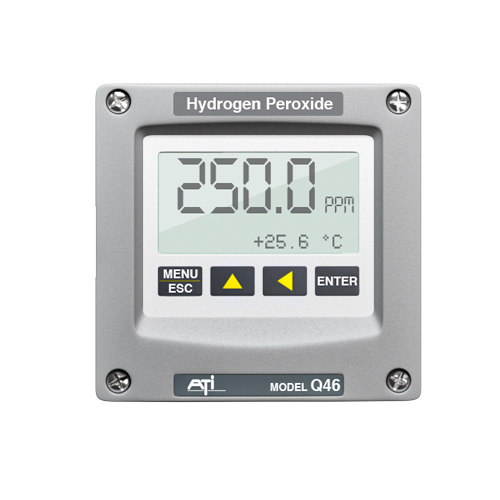

Because measuring the SO3 ion in solution is relatively difficult, the Q46S/66 Monitor takes a different approach to the measurement, employing a unique gas-phase method to continuously monitor sulfite without contact between the sensor and the water sample. In operation, a small amount of sample is pumped into the system and mixed with acid. In acidic solution, the sulfite ion is converted to sulfur dioxide. The mixed sample flows into a special chamber where the sulfur dioxide is stripped from the sample. A gas conditioning module prepares the gas sample for measurement prior to contact with a special sulfur dioxide gas sensor designed foe the system. Sensor signals are amplified and displayed on a large format, backlit LCD display in the Q46S electronics unit.

Installation

A sample inlet overflow block is provided on the bottom of the chemistry module. Sample is connected using ¼” id flexible tubing, with a recommended flow rate of 5-20 gallons per hour. While the monitor uses only a small fraction of this sample, the higher flow keeps sample delivery times to a minimum. Excess sample simply overflows to a gravity drain chamber requiring a ½” id flexible tube.

Sulfite monitoring systems are extremely easy to operate and maintain with acid usage of one gallon every 25 days at standard flow rates. Sample and acid are pumped using long life peristaltic pump tubing that requires replacement approximately every 6 months. Pump heads are designed for easy tube changes, requiring about 10 minutes to replace both pump tubes. The sulfite sensor requires no maintenance other than an occasional visual inspection to insure that no deposits have collected due to airborne particulates.

The gas stripping technique for monitoring sulfite in solution provides an extremely sensitive on-line monitor. Measurements down to low parts per billion can be done easily and zero and span stability inherent in the sensor allow for monthly calibration cycles.