Description

Description

Peracetic acid (PAA) is an extremely strong oxidizer widely used in the food industry for disinfection of piping systems and processing equipment. It is also used for spray washing of food products and for disinfection of cooling water systems. As a disinfecting agent, PAA is often preferred because it produces no harmful breakdown products.

As with any disinfection system, maintaining proper residual values is the key to effective pathogen control. To facilitate reliable chemical feed control, ATI has developed an on-line monitor cable of providing real time measurement of low levels of PAA in solution. The Q46/85 Peracetic acid monitor uses a direct sensing polarographic probe mounted in a flowcell to measure PAA residuals in a flowing water stream. A permeable diffusion membrane isolates the sensing electrodes from the measured sample, providing long term stability without electrode fouling problems. The measurement is selective for PAA and is not affected by changes in hydrogen peroxide in solution.

Peracetic acid sensors are amperometric devices isolated from the water by a permeable membrane. As PAA diffuses through this membrane, it comes in contact with an active electrode and is reduced on the surface. The net effect is that the sensor generates a current proportional to PAA concentration. An integral RTD in the sensor provides for automatic temperature compensation, allowing the sensor to operate accurately over a range of 0-50°C.

Peracetic acid sensors are capable of operating over a fairly broad concentration range, from a low range of 0-20 ppm up to a high range of 0-2,000 ppm. Systems will operate with good sensitivity down to 0.2 ppm and respond to changes in concentration within about 60 seconds, making them useful for automatic control.

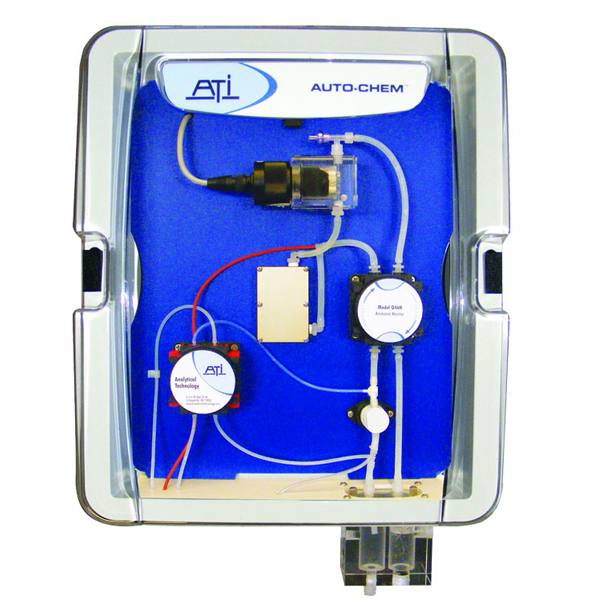

Peracetic Acid sensors require a steady flow of sample across the membrane at the tip of the sensing assembly. Options for flowcells, including the standard constant-head overflow systems and a sealed flowcell for pressures up to 50 psi. For simplicity of installation, complete flow control assemblies are available. Panel assemblies re available with or without a flow switch and can greatly reduce installation time. For open tank installation, a submersible sensor is available. Sample agitation is required as PAA sensors cannot be used in still water.