Description

Description

ATI’s Q46/88 Suspended Solids Monitor provides real time monitoring of suspended solids in a variety of water and wastewater applications. A submersible sensor immersed in process tanks or effluent channel senses particulates in the water using an optical backscatter technique that allows measurement over a wide range. Results are displayed on the Q46 electronic unit mounted near the sensor with a variety of outputs provided as standard.

Monitoring suspended solids in wastewater and industrial process water can be useful for either process control or for alarming of unusual conditions. In biological treatment systems, monitoring suspended solids in the aeration tank can assist operators in maintaining optimum MLSS (Mixed Liquor Suspended Solids) concentration. In industrial clarifiers, suspended solids monitoring can warn of upset conditions that might result in the discharge of solids that exceed plant permits.

Suspended solids sensors are optical devices operating in the infrared region. Unlike turbidity sensors that us 90° scatter to optimize sensitivity, suspended solids sensors use backscatter to allow solids measurements at much higher levels. Operation with infrared light insures very long sensor life and minimizes the effects of changing sample color.

Sensors are designed to withstand the rigorous conditions of wastewater and industrial streams and to last for years of service with nothing more than occasional cleaning of the sensing surface. There are no protruding surfaces near the sensing element to avoid accumulation of fibrous materials. The sensor is simply pipe mounted adapters available.

Optical sensors used for monitoring biologically active systems such as aeration tanks or aerobic digestors will require periodic cleaning to maintain the integrity of the measurement. Biological slime deposited on the optical surface will degrade the ability to transmit IT light into the sample. The frequency of cleaning varies widely depending on the turbulence in the process. Course bubble diffusion systems tend to scour the sensor while fine bubble diffusion system result in more rapid sensor fouling.

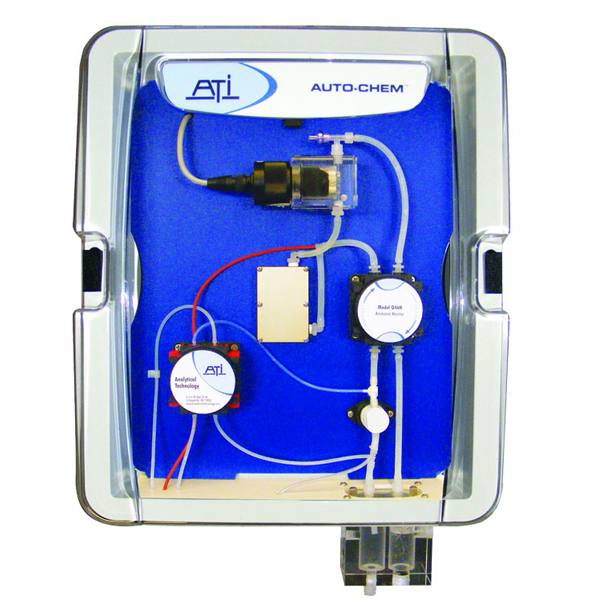

Cleaning can be done manually by simply wiping the sensor as needed, but ATI also offers an automatic air-blast cleaning system as an option. The Q-Blast air cleaning system is controlled by the Q46/88 Suspended Solids Monitor and provides a compact air compressor system that periodically applies pulses of compressed air across the optical surface to remove accumulated biofouling. This system greatly reduces the requirement for manual maintenance, with cleaning frequency programmed to occur as often as necessary.

Suspended Solids sensors are generally pipe mounted using 1″ PVC pipe. A special 1″ FNPT adapter screws to the back of the sensor and can be purchased separately or as part of a complete mounting assembly. Q46/88 Monitors may be either wall or pipe mounted and are weatherproof for outdoor use. In addition, the Q46 electronics can be separated from the sensor by up to 100′ using a function box and electronic monitor may be panel mounted using an optional panel mount bracket kit.